Fab-lite light wafer fab model: Hotchip’s business strategy to disrupt the semiconductor world and shape industry innovation.

In the precision world of semiconductors, the birth of a chip is complex and exquisite. It is not only a technical process, but also a comprehensive challenge covering design, manufacturing, packaging, testing, and sales. Each step is crucial, and diversified business models have been formed based on the different stages undertaken by semiconductor companies. The evolution of business models is not only a change in business processes, but also a vivid reflection of the development trend of the semiconductor industry. How this model reshapes corporate strategy and drives industry progress, let’s uncover this mysterious veil together.

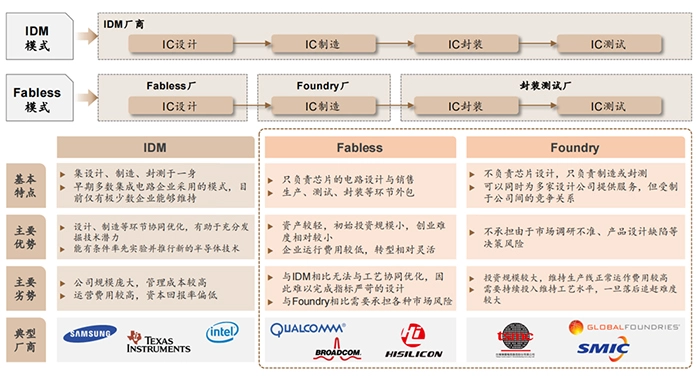

As the core driving force of global technological development, the evolution of the semiconductor industry’s business model is directly related to the pace of technological innovation and industrial upgrading. Since the 1980s, the business model of the semiconductor industry has undergone significant evolution. From the full chain control of IDM (Integrated Device Manufacturer) mode to the rise of Fabless (fabless semiconductor design company) and Foundry (foundry) modes, the industry structure is gradually shifting towards specialization and division of labor cooperation. In the 21st century, with the development of semiconductor and integrated circuit technology and the diversification of market demand, the Fab lite (light wafer fab) model has emerged as an important mode for connecting design innovation and efficient manufacturing.

Comparison of Traditional Semiconductor Industry Operation Models:

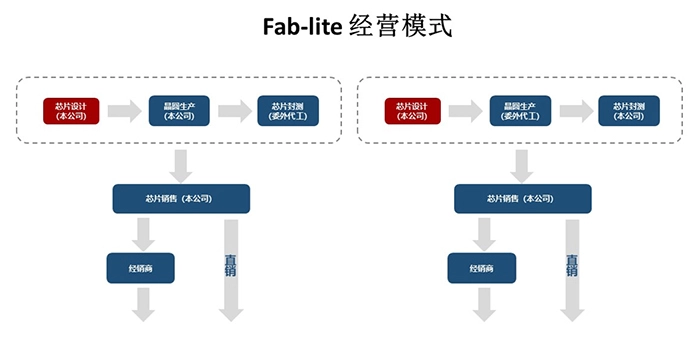

The Fab lite model, also known as the light wafer fab model, is an innovative hybrid operation model in the semiconductor industry. This model is a strategic model adopted by semiconductor companies to reduce investment risks and reduce asset value. It combines the characteristics of IDM and outsourced wafer foundry. In this mode, relevant manufacturers or IDM enterprises retain some of their own production capacity, independently complete key production processes, and outsource non critical production processes while ensuring chip quality and reliability. Therefore, it is called the “light wafer” mode. This model can provide low-cost and more flexible solutions for manufacturers who need to expand their chip manufacturing capacity, and respond quickly to market demand. For example, IDM manufacturers such as Texas Instruments and ADI outsource some of their business to contract manufacturing. Intel, the leader of IDM manufacturers, has also outsourced some of its business to TSMC in China. This model can reduce the capital investment and operating costs required for large-scale manufacturing, while strengthening the key technologies and independent control capabilities of each link in the industry chain, comprehensively enhancing competitiveness from the perspectives of new product technology and process development, industry chain collaboration, and product delivery.

The Fab lite model is becoming a development trend for analog chip manufacturers who need to independently control key production processes and production capacity.

The advantage of the Fab lite model lies in its flexibility and cost-effectiveness. It allows enterprises to flexibly adjust their production scale and methods based on market demand and their own strategies, and reduce fixed costs and risks through external cooperation. This model promotes technological cooperation and knowledge sharing, helping enterprises quickly adapt to market changes and accelerate technological innovation. At the same time, the Fab lite model can also help companies optimize investments, concentrate resources on core competitiveness and innovation, thereby improving market competitiveness and financial performance. Through this strategy, companies can effectively control costs and risks while maintaining technological leadership and market responsiveness.

Shenzhen Hotchip Technology Co., Ltd. is an excellent example of operating under the Fab lite model. Hotchip not only maintains its research and development and production capabilities in key technology areas, but also effectively expands its production scale and market response speed through cooperation with external contract factories. This model enables Hotchip to maintain technological leadership while also possessing the ability to quickly adapt to market changes. In addition, the Fab lite model has also helped Hotchip achieve higher cost efficiency. Through selective internal manufacturing and external cooperation, Hotchip is able to effectively control operating costs while maintaining high-quality product standards. This strategy not only enhances Hotchip’s market competitiveness, but also brings it a more stable profit margin. Truly achieved complete chain control from research and development to production and sales. The success of Hotchip once again proves the effectiveness and foresight of the Fab lite model in the semiconductor industry.

Against the backdrop of rapid global economic and technological development, the competition in the semiconductor industry is becoming increasingly fierce. The Fab-lite model, as an emerging business strategy, provides an effective way for semiconductor companies to survive and develop. The practice of Shenzhen Hotchip Technology Co., Ltd. shows that the Fab lite model can help enterprises achieve the dual goals of technological innovation and cost-effectiveness, and strengthen their competitive position in the global market. As more semiconductor enterprises adopt this model, we have reason to believe that Fab lite will play an increasingly important role in promoting the progress of semiconductor industry!