Hotchip Technology focuses on the fourth and a half generations of high-precision MEMS temperature sensors, marking a new milestone in technological innovation and precise temperature measurement.

Shenzhen Hotchip Technology Co., Ltd. was established in 2008 and is headquartered in the Digital Innovation Center of Longhua District, Shenzhen. The group has total assets of over 1 billion yuan: it has chip research and development and process centers in Suzhou and Taipei, and has established advanced intelligent manufacturing centers for chip frame packaging, substrate packaging, wafer level packaging, etc. in Jiangsu, Shandong, and Guangxi. Its product lines include Power+(power related), MEMS+(sensors), Display+(display related) AI+WBS (Artificial Intelligence+Third/Fourth Generation Wide Bandgap Semiconductor Materials) and other commercial/consumer chips or modules.

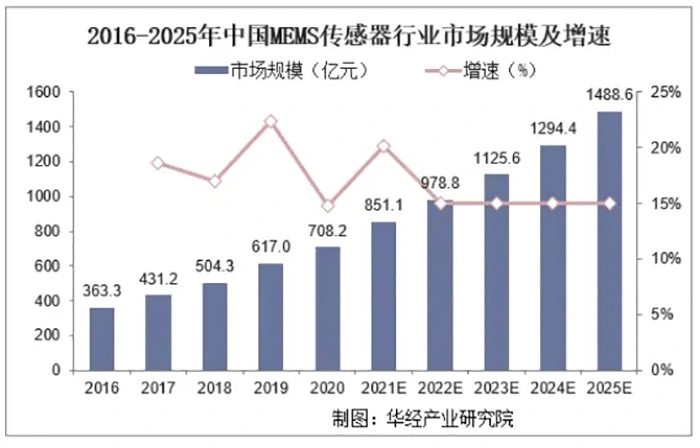

Market prospects of MEMS sensors – temperature sensors

From 2014 to 2022, the global sensor market has experienced significant growth, showing a 2.5-fold expansion. In this change, silicon-based MEMS sensors have become particularly important and have almost become mainstream products in the market. By 2020, the global market size of MEMS products has climbed from approximately 11.5 billion US dollars in 2014 to approximately 22 billion US dollars. In the Asia Pacific region, the demand for MEMS products in China is particularly strong, which is due to both the demand for consumer upgrading and the promotion of industrial upgrading. In fact, in recent years, the growth rate of China’s MEMS market has continued to exceed the global average, one of the main reasons being that the development of the Chinese market started relatively late and at a low starting point. This rapidly growing market demand not only indicates enormous market potential, but also provides rare development opportunities for domestic MEMS design and manufacturing enterprises.

In 2001, the Chinese government included new sensors as a key research and development project. Since then, China has had the production capacity of mainstream MEMS devices, and the market share of domestic manufacturers has rapidly increased. Overlapping the trade friction in 2020 and the COVID-19, domestic manufacturers have realized the importance of localization of the industrial chain, and the demand of the industry to purchase domestic MEMS devices is increasing. Common MEMS sensors include inertial sensors, MEMS microphones, temperature and humidity sensors, gyroscopes, acceleration and pressure sensors, gas sensors, etc.

A temperature sensor is a device used to measure and monitor the temperature of an environment or object. It can convert temperature changes into electrical or digital signals for further processing, display, or recording. Temperature sensors are widely used in various applications, including meteorological monitoring, industrial automation, electronic devices, healthcare, automotive, and consumer electronics. The market size of temperature sensors is expected to grow from $8.28 billion in 2023 to $11.23 billion in 2028, with a compound annual growth rate of 6.28% during the forecast period (2023-2028).

Hotchip’s fourth and a half generation high-precision MEMS temperature sensor

The Suzhou R&D team of Hotchip Group has been focusing on the design, production, testing, and OEM of high-precision MEMS temperature sensor chips based on fourth generation metal oxide semiconductors for eight years. They mainly engage in the research and development, production, and sales of MEMS temperature sensor chips, temperature sensor chips, and temperature sensor modules, and continue to build an “end-to-end cloud” IoT ecosystem. In the future, they will mainly be applied in the fields of home appliances, communication, and industrial control, and gradually expand their applications in automotive, medical, and other fields.

The core technology team of the company has gathered numerous senior experts who have years of in-depth research and rich process experience in the fourth generation metal oxide semiconductor materials and sensor industry. This field not only requires a profound understanding of materials science, but also involves the comprehensive application of interdisciplinary knowledge such as mechanics, electronics, materials science, and semiconductors. Our company is well aware of the importance of technological innovation, and therefore attaches great importance to the professional growth and skill improvement of our R&D personnel. Therefore, the company has formed a team with both high education and strong innovative spirit, each with profound professional backgrounds in their respective fields. This team not only has extraordinary achievements in technology research and development, but also has accumulated rich experience in the development of fourth generation metal oxide semiconductor materials and sensors, enabling the company to maintain a leading position in the industry.

The temperature sensor chip we produce combines the advantages of thermal resistance and IC temperature sensors, and is a new type of MEMS temperature sensing technology with the advantages of its new nanomaterials. It has advantages in temperature measurement accuracy, small packaging, and low cost that traditional temperature sensors cannot match.

The company has currently received key funding from Suzhou’s technology leading talent entrepreneurship projects. The fourth generation semiconductor products developed by the company have also won the second prize in the industry finals of the 15th China Shenzhen Innovation and Entrepreneurship Competition, the third prize in Longhua District, Shenzhen, and the national top 100 in the field of new generation information technology; The company has successfully developed a fourth generation semiconductor sensor chip, which is currently in the pilot stage. The technical specifications and cost of its product far exceed those of similar products at home and abroad.

The company has currently established a production and packaging testing line for high-precision MEMS temperature sensors, which can complete everything from nano material synthesis to wafer level doping and packaging testing on one production line, achieving a completely independent IDM production and manufacturing mode. Since its establishment, the company has received strategic investment from state-owned institutions and recognition from industry-leading suppliers/customers; In the future, the company will continue to deepen its research and development of chips and consolidate its manufacturing foundation, steadfastly fulfilling its mission of making the world fall in love with Zhonghua Chip.